The manufacturing sector contributes more than $8 trillion to the US economy and is a crucial part of the country's financial foundation. However, the industry's growth and long-term success rely on various factors, with the most significant being the quick adoption of new technologies. The integration of Information Technology (IT) and Information Technology Enabled Services (ITES) presents a formidable challenge. Companies are working to balance their existing systems with the opportunities brought by Industry 4.0 technologies. While the challenges in manufacturing might seem obvious, finding effective solutions is difficult, especially for high-level executives.

As the landscape of manufacturing evolves in the era of Industry 4.0, five key challenges stand out as pivotal challenges to IT/ITES integration

McKinsey's data indicates that around 50% of product launches fall short of their targets. The ability to address this in a swift and effective manner requires large manufacturers to embrace a digital-first mindset, regardless of their industry. This digital-first approach enhances flexibility and innovation, allowing rapid adaptation and decision-making, crucial for the survival of digitally native and smaller businesses globally.

Organizations have intricate legacy systems designed for specific purposes. Upgrading can seem overwhelming as businesses have been shifting to new applications over time . While adapting modern backend platforms is vital for seamless integration with the growing app environment, navigating through the legacy systems conundrum still seems like a challenge for most CIO’s.

The latest phase of the fourth industrial revolution produces abundant real-time data through shop floor and management interactions. This data offers potential for cost-saving predictive maintenance. Yet, manufacturers worry about hardware and strategy hurdles for utilizing it effectively. Accumulating irrelevant data can hinder historical analysis over time. Aligning operational and informational data from the start, involving stakeholders, is vital for successful utilization.

Regardless of a company's size, navigating supply chain complexities comes at a significant cost. Dynamic operating markets demand real-time information to stay competitive. Manufacturers strive to find unified solutions for real-time visibility into their supply chains, addressing issues related to forecasting, demand management, sales, and operational planning. Simultaneously, managing inventory optimally poses a challenge. Thankfully, market giants like SAP, IBM, Oracle, and others have developed optimal solutions, but selecting the right tool remains an intricate process.

Organizations have transitioned from viewing IT as a mere cost center to treating it as a revenue center. IT decision-makers are now tasked with forging pathways to establish new revenue streams for their organizations, facilitated by enabling IT. As Albert Einstein aptly stated, "We cannot solve our problems with the same level of thinking that created them. " Embracing IT as a revenue enabler represents a significant shift in mindset, aligning IT strategies with overarching business objectives.

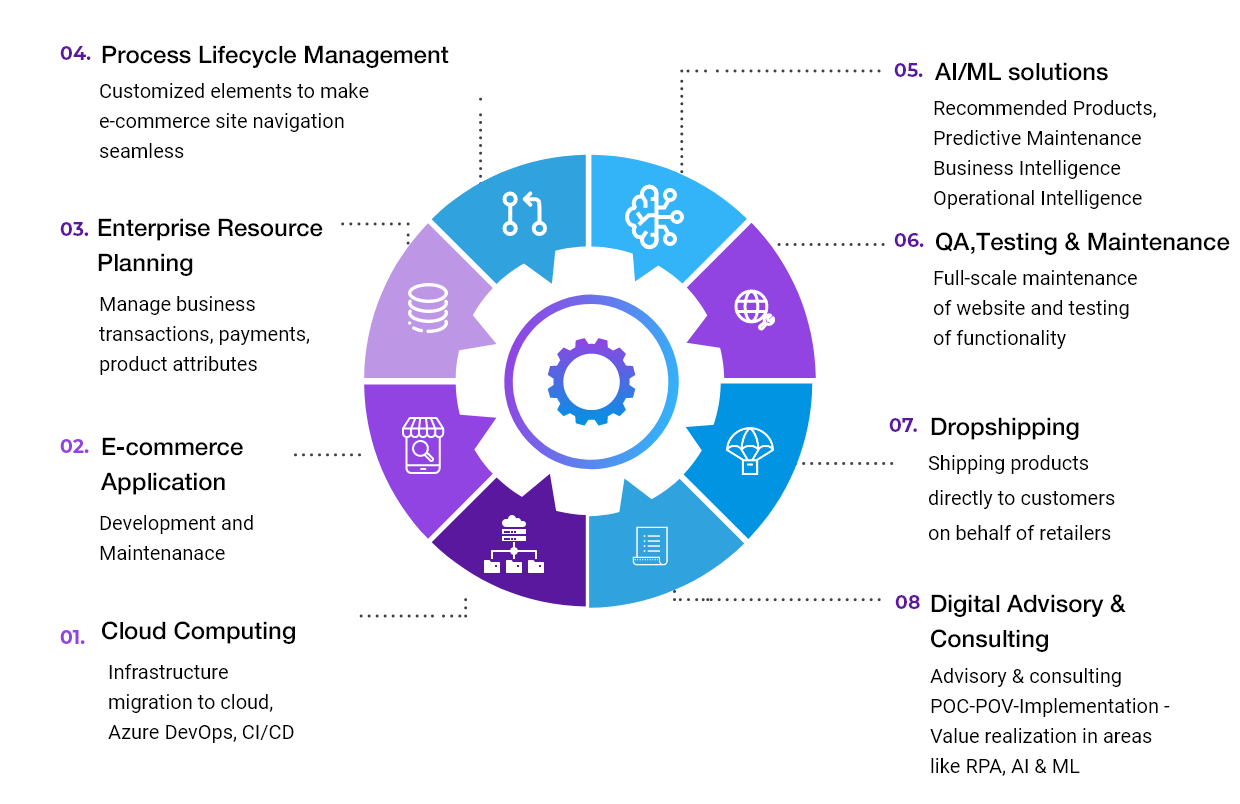

For nearly a decade, Maganti IT has engaged with global manufacturing clients, offering valuable insights into technology challenges faced by these firms, transcending industry boundaries and guiding you in reaping genuine value from your Industry 4.0 venture. With a breadth of expertise in manufacturing advisory, strategic consulting and IT - we pave the way for smoother digital transitions, ensuring top-notch operations, cost savings, and better-quality management.

Team up with our AI/ML experts to push the boundaries of innovation. Talk to us.