Improves OEE in Manufacturing

If you're in the manufacturing industry and want to identify potential cost drivers in your operations or evaluate your productivity levels, then OEE is an aspect worth delving into. Overall Equipment Effectiveness (OEE) is a top-tier key performance indicator (KPI) within the manufacturing and industrial automation sectors that calculates the efficiency of production equipment or systems. It’s a crucial metric for boosting productivity, increasing return on investment, reducing costs, and maintaining market competitiveness. Higher OEE scores mean improved quality products and more reliable machine performance.

Enhancing your OEE metrics can lead to significant benefits for manufacturers, such as an average increase in equipment utilization of 5% to 15%, according to the World Class Manufacturing (WCM) Institute. Regular monitoring of your OEE and production lines operations can help identify bottlenecks and points of failure promptly. This ensures consistent process optimization across all production lines, driving your operations towards higher levels of efficiency.

Let's understand the components of an OEE score

Availability:In terms of OEE, availability measurement involves monitoring the incidence and length of both planned and unplanned downtime and interruptions. According to ideal standards, manufacturers should experience no stoppage time to achieve a 100% rating in availability.

Quality:In terms of OEE, quality refers to the percentage of parts made that meet or exceed the set quality standards. These are usually called "Good Parts".

Performance:Performance is a production velocity metric that incorporates activities leading to time loss. It is frequently assessed by comparing optimum cycle durations against actual cycle durations.

Let's visualize this situation

Availability:A machine was set to run for 8 hours but only operated for 7.5, marking an availability of 87.5%.

Performance:The machine, with a maximum capacity of producing 5,000 units in an 8-hour shift, only generated 4,400 units, giving a performance rate of 88.0%.

Quality: Out of the 4,400 units produced, only 4,200 passed the quality check, resulting in a quality rate of 93.2%.

From these figures, the OEE is calculated as 0.875 x 0.88 x 0.932, which equals 72%.

Over the past decades, many companies have been working at OEE levels between 65–70%, enabling a shift from purely reactive to more proactive manufacturing. But there is a possibility of boosting OEEs between 85-90%, this impressive 15–20% increase can only be achieved by integrating advanced AI technologies that apply artificial intelligence and machine learning directly to industrial equipment endpoints.

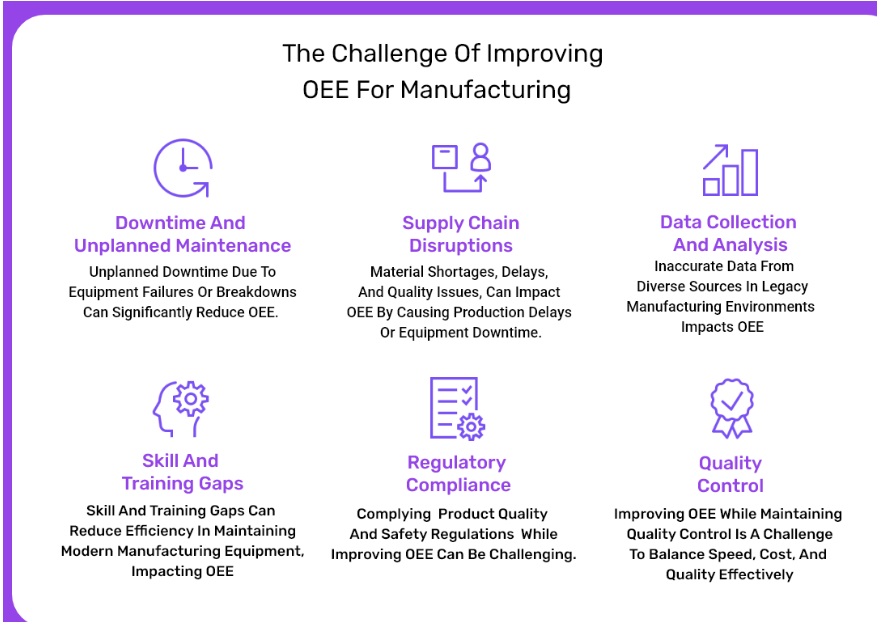

Chasing a high OEE percentage is a long-awaited target for manufacturers - it means that your manufacturing operations are utilizing the resources effectively, meeting production targets consistently, and delivering quality products to customers. But getting that OEE score up isn't easy - it's a constant uphill battle.

From addressing equipment downtime to optimizing processes and harnessing the power of data, to be more efficient and profitable - there's a whole host of challenges that can throw a wrench in the works when it comes to lifting that OEE score in manufacturing.

As manufacturers continue to tackle the challenges of the modern operating environment, more of them are turning to data and technology to solve current problems and plan for the future. Predictive analytics can be a game-changer in manufacturing, helping to boost the overall effectiveness of equipment by spotting possible hiccups in the production line before they even happen.

This happens by gathering real-time data from all over - sensors, machinery, the production process, quality checks and storing it for analysis in data warehouses. Then, we use a blend of technology and data science to make sense of this data through predictive models.

Now, let's dive into how predictive analytics can make a difference:

Early Warning of Equipment Failure: Let’s say that a production line machine exhibits unusual vibration and high energy use in your manufacturing unit. Predictive analytics leverages historical data, real-time equipment stats, and advanced algorithms to anticipate equipment malfunctions. The system cross-references the machine's history and identifies potential bearing issues. The maintenance team, alerted ahead of time, spots signs of early wear and replaces the bearings before failure occurs, guaranteeing continuous production. This approach promotes proactive maintenance, minimizes unexpected downtime, and enhances operational efficiency.

Enhanced Quality Control: Foreseeing the future of manufacturing, predictive analytics enhances quality control and boosts efficiency by analyzing past data to identify subtle shifts that could signal potential defects. When it detects such a change, an alert is generated, prompting immediate action from the production manager. This might involve adjusting certain parameters or changing the raw materials used. The result? Improved product quality, fewer costly recalls, and enhanced Overall Equipment Effectiveness (OEE).

Predictive Inventory Management: Predictive analytics is a valuable resource for manufacturers which helps them fine-tune their inventory levels and enhance the Overall Equipment Effectiveness (OEE) by forecasting future demand for raw materials and finished products. This foresight allows manufacturers to avoid material shortages, cut down on excess inventory, and boost production efficiency. It also enables them to respond rapidly to shifts in demand and make necessary adjustments, leading to a more streamlined operation.

Is your manufacturing business operating at its peak efficiency? Are you hitting your Overall Equipment Effectiveness (OEE) targets? Leverage our no-cost OEE evaluation to uncover operational inefficiencies, budget leaks, and productivity bottlenecks. Our team of seasoned specialists will assess your current processes, pinpoint areas for improvement, and collaborate with you to formulate an optimization strategy, providing continuous support throughout implementation.

With over two decades of specialization in tech solutions for the manufacturing industry, we have a deep-seated understanding of its intricacies. Our prowess lies in data analysis and engineering, and our track record includes successful partnerships with numerous manufacturers, providing bespoke dashboards, ERP systems, CMS platforms, and predictive manufacturing solutions.

Ready to launch your journey towards operational excellence? Talk to our SME’s today.